Climate Action

2027 - Aim to match electric power needs with renewable energy in DX (Device eXperience) Division and all global operations sites

2030 - Aim to achieve net zero carbon emissions at the DX (Device eXperience) Division (Scope 1 & 2)

2050 - Aim to achieve company-wide net zero carbon emissions (Scope 1 & 2)

Samsung Electronics

is one of the world’s largest ICT (Information & Communication Technologies) manufacturing company that makes products in all areas of the electronics industry — from semiconductors to smartphones, TVs and home appliances.

RE100 cites* Korea, where many of Samsung Electronics’ production facilities are based, as one of the most challenging countries to source renewable energy. This is in part due to the country’s renewable energy market, where procurement options for corporations have begun to expand but remain limited. Additionally, the electric power needs of semiconductor manufacturing facilities have continued to increase with the expansion of Samsung Electronics’ production capacity to meet global demand. However, the company will aim to achieve renewable energy use more proactively, acknowledging the urgency of today’s climate challenges.

*Source: "Revealed: the most challenging places in the world for business to source renewable electricity" (RE100/Climate Group/CDP, 2020)

*Based on direct and indirect greenhouse gas

emissions of 17.4 million tonnes in 2021

(Annual greenhouse gas emissions of 2.1 tonnes per sedan, Korean Energy Corporation)

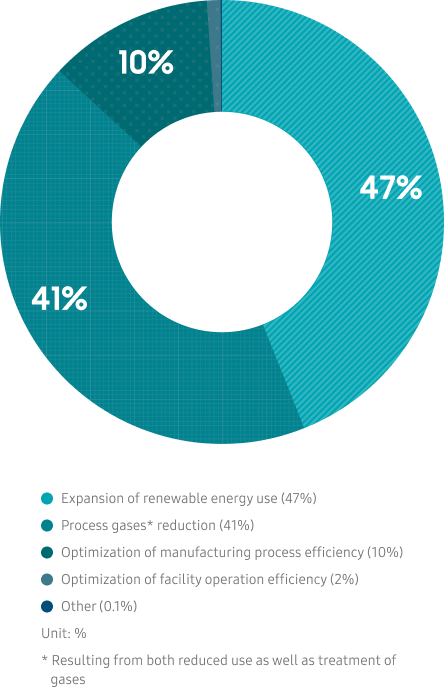

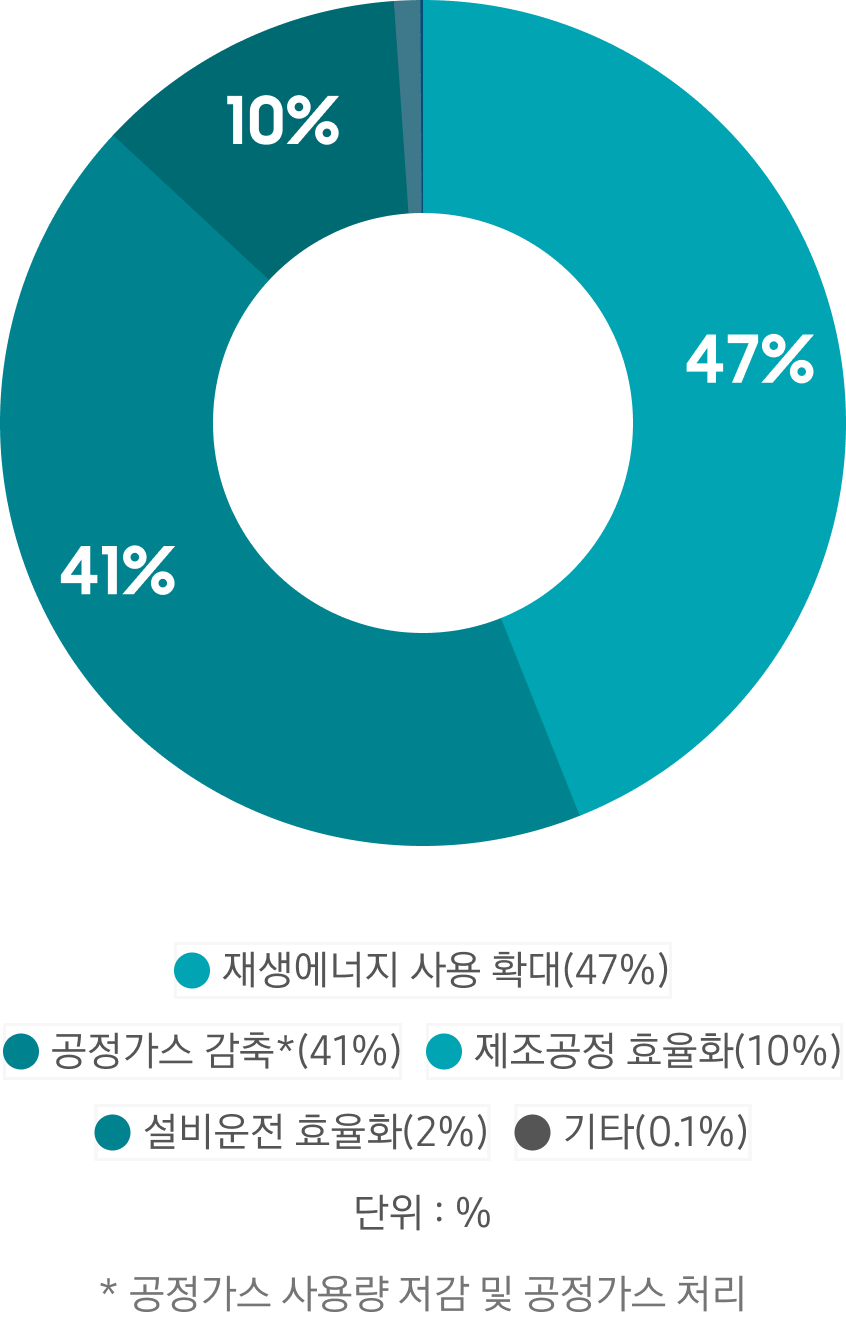

In 2022, through a total of 474 greenhouse gas reduction projects, we reduced greenhouse gases by 10.16 million tonnes per annum.

By using innovative technologies that significantly improve process gas treatment efficiency,

Samsung Electronics can keep direct carbon emissions (Scope 1) down even as production increases.

We aim to transition to

100% renewable energy by 2050

2018 - Declared to expand the use of renewable energy (100% in the U.S., Europe and China)

2020 - Transitioned to 100% renewable energy use in the U.S., Europe and China

2022 - Matched electricity use in Southwest Asia with renewable energy

2025 - Aim to match electricity use in Central and South America with renewable energy

2027 - Aim to match electricity use with renewable energy for all business sites(excluding Korea) and DX(Device eXperience) Division

2050 - Aim to match electricity use with renewable energy for all global operations

Continued carbon emission

reductions in upstream and

downstream operations

Manufacturing is only one of many stages in the entire product life cycle. We strive to reduce carbon emissions across all stages of the product life cycle including distribution, sales, and use in collaboration with our consumers, suppliers, and other stakeholders.

In particular, we plan to utilize ultra-power-saving technology for semiconductors, which is expected to drastically reduce the memoryrelated power consumption of data centers and mobile devices from 2025. We plan to apply the technology to the leading models of our seven major product categories (smartphone, refrigerator, washer, air conditioner, TV, monitor, and PC) and improve their power consumption by 30% by 2030 compared to the 2019 models with equivalent performance.

Energy efficiency of

products 1)2)

| 2020 | 2021 | 2022 | |

|---|---|---|---|

| Amount of GHG emissions reduced in the product use phase | |||

| Amount reduced by year (1K tonnes CO₂e) | 31,671 | 32,906 | 914(18,909)* |

| Energy efficiency improvement rate | |||

| Product energy consumption reduction rate (%) | 32 | 33 | 2.6(18)* |

We established the LCA process to accurately assess the

environmental impact and carbon footprints of our

semiconductor products across their entire lifecycles. Based

on ISO 14040, 14044, and 14067, the operation of this process

was verified by a third-party organization to ensure the

credibility of all data produced.

To reduce the environmental impact of semiconductor

products, we plan to establish a comprehensive management

system of their carbon emissions and their use of water and

other resources.